About UsWelcome

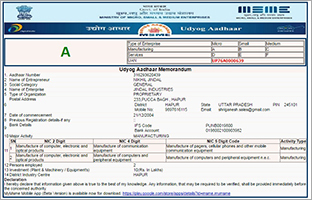

to Jindal Industries, your trusted partner in the OEM business.

Established in 2004, we proudly operate out of Hapur, Uttar Pradesh,

India. Specializing in the manufacturing of mobile accessories, our

product range includes mobile chargers, USB data cables, neckbands, TWS

earbuds, and Bluetooth speakers, along with repair wires for neckbands.Operating

globally, our branch office in Karol Bagh, New Delhi, serves as a hub

for international trade, ensuring seamless transactions and superior

customer service worldwide. Our

strong partnerships in China enhance our capabilities, as our dedicated

QA team ensures the procurement of top-notch raw materials. These

materials are then meticulously designed and manufactured in our Indian

factory, ensuring that our products meet the highest standards of

excellence.At

Jindal Industries, we prioritize innovation, quality, and customer

satisfaction, offering tailored OEM solutions to meet your specific

needs. Become a partner with us as we continue to lead the way in the

mobile accessories industry with our dedication to superior products and

services.OEM GuidelinesAt JINDAL INDUSTRIES, OEM (Original Equipment Manufacturer) guidelines are essential part of our manufacturing process.Heres an overview of our Brand Guidelines that we strictly follow:Quality Standards

- ISO Certification:

Ensuring products meet ISO standards, all our products and

manufacturing products are ISO 9001 for quality management certified.

- Material Specifications: We use best in class products as part of our manufacturing process while maintaining the standard protocols.

- Testing Procedures: Real capacity testing measures are being followed.

Design and Engineering

- Design Specifications: We follow detailed requirements for product design, including dimensions, materials, and functionality for our clients.

Manufacturing Processes

- Production Methods: Approved methods for manufacturing processes, including machining, welding, and assembly as key parts of our production.

- Process Control: To maintain the quality standard we keep a strict check-up as part of the activity during and after completing the project.

Compliance and Certification

- Regulatory Compliance: We

ensure that all the products which we are developing for our clients

comply with relevant laws and regulations (e.g., safety, environmental).

Documentation and Reporting

- Documentation Standards:

Requirements for technical documentation, user manuals, and product

labels are done as per the requirement of the clientele and the product

type.

- Reporting Procedures: Protocols for reporting production metrics, quality issues, and compliance status.

Aftermarket and Support

- Warranty Policies: Guidelines for warranty coverage and claims processes is part of our add on service and is subjected to client requirement.

- Technical Support: Our technical staff and support team is always available for your assistance.

- Spare Parts Management: Requirements for availability and management of spare parts.

Intellectual Property and Confidentiality

- IP Protection: We reserve all rights as part of our manufacturing process and after handing over the IP is transferred.

- Confidentiality Agreements: Policies for handling confidential information between OEM and partners. We maintain a high confidentiality agreement.

Health and Safety

- Workplace Safety Standards: Ensuring the manufacturing process adheres to health and safety regulations.

- Product Safety: Ensuring products are safe for use and meet all safety standards.

Implementation and AdherenceImplementing OEM guidelines typically involves:

- Training Programs: Regular training for employees and partners on OEM guidelines.

- Audits and Inspections: Periodic audits to ensure compliance with OEM guidelines.

- Continuous Improvement: Ongoing efforts to improve processes, quality, and compliance.

OEM

guidelines are crucial for maintaining high standards in production,

ensuring product quality, and achieving customer satisfaction. Adhering

to these guidelines helps in building a robust and reliable

manufacturing process, fostering trust and long-term relationships with

customers and partners.

About Our Founder- Mr. Nikhil Jindal

Nikhil

Jindal, founder of Jindal Industries, brings 24 years of extensive

experience to the table. He spent 8 years working with renowned brands

like Airtel, Sony, and MDH Masale in corporate and distribution roles.

Sixteen years ago, he leveraged this experience to start Jindal

Industries, focusing on designing and manufacturing mobile accessories

under the brand name Goodit.

Originally

from Hapur, Uttar Pradesh, Nikhil holds a Bachelor of Commerce degree

from CCS University. His deep understanding of business operations and

market dynamics has driven the companys growth and success. Jindal

Industries, headquartered in Hapur, has become a leading name in the

mobile accessories sector, offering products such as mobile chargers,

USB data cables, neckbands, TWS earbuds, Bluetooth speakers, and

neckband repair wires.

Nikhil

emphasizes quality and innovation in his leadership. He established a

Quality Assurance team in China to source the finest raw materials,

ensuring high standards. These materials are then shipped to the Indian

factory for production. Additionally, he expanded the companys reach

with a branch office in Karol Bagh, New Delhi, to manage global trade

activities.

Under

Nikhil Jindals visionary leadership, Jindal Industries continues to

thrive, setting industry standards and meeting the dynamic needs of

customers.

|

| |

|

|